For several years, we have discussed how to make efficient 160m antennas. The inherent problem with all the alternatives is that they need to be very large, which is especially difficult with portable operations. It’s possible to compromise height and/or length, as has been our general approach with a low-hanging dipole. However, this reduces the efficiency and bandwidth of the antenna.

If we exclude sub-optimal options, like shortened or low-hanging antennas, the discussion usually turns to various concepts for quarter-wave verticals. We made one of those as our 80m antenna, using the largest glass fiber mast Spiderbeam offers. However, for the 160m band, while theoretically possible, 40 m high masts are both impractical and expensive. The discussions then turn to using a quadrocopter to support a lightweight antenna wire. While possible, it is quite an expensive approach. For a student club with a modest budget, this has not yet materialized.

A cheaper alternative would be to support the antenna with a large floating balloon. This is not free either as we need a balloon, large amounts of wire, hydrogen, and not least a hydrogen regulator to fill the balloon in a controlled manner. Fortunately, a series of events unfolded during the spring that made it economically viable: LB1DJ met LA2CMA at a job interview, who offered to lend us his hydrogen regulator, LB5FJ found some army surplus weather balloons online, and LA2T provided sufficient amounts of thin copper wire. With the help of LA2HMA we could buy the hydrogen through Studentersamfundets agreement with Linde Gas.

With everything acquired, it was time to test it. After a thorough study of the aerial photos, we chose the large parking lot of “Vassjellet Winterpark” as our test-QTH. The large open area had space for all guy wires and radials, and we expected there to be relatively few people around at this time of the year.

On the Saturday two weeks before Field Day, LB1DJ and LB5DH met to do the final preparations and travel to the test site. The final preparations took a little longer than anticipated, but at 14.30 we were finally underway.

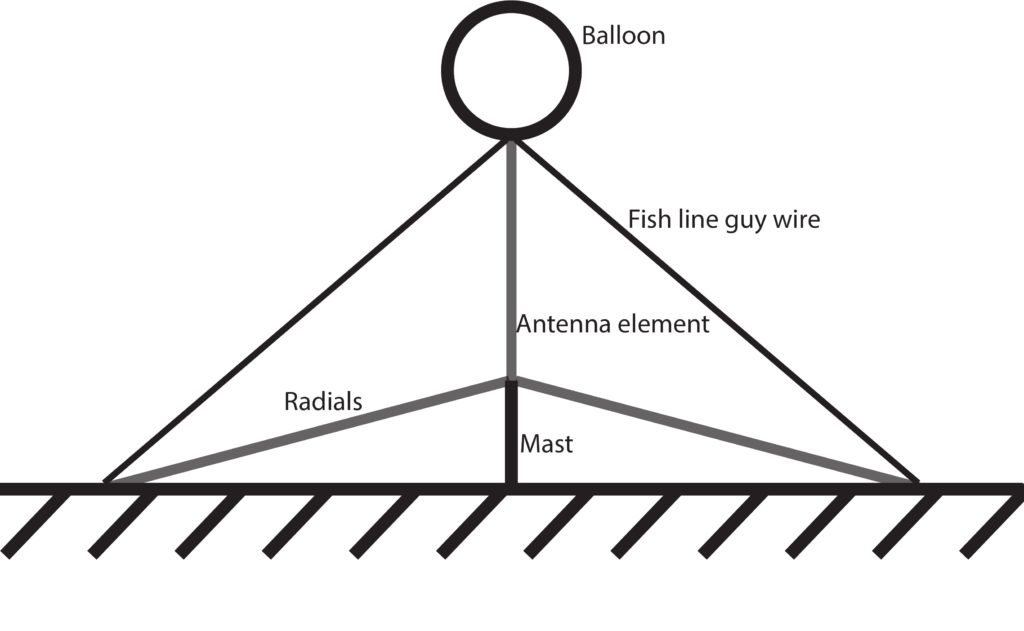

When we arrived, we found that the barrier was open, which allowed us to drive to the center of the parking lot. We unloaded all the equipment and prepared to fly the antenna. The parking lot was made of dry rock, which would have made a horrible ground plane. Fortunately, we planned to use elevated radials. The balloon was not strong enough to carry all the radials, at least not tightly, so the plan was to use our 12m spiderbeam glass fiber mast to support the radials and have the balloon lift only the element. There was only one issue: we forgot the mast.

After driving back to get the mast and buying some more fishing lines on the way, we started readying the antenna. Wire antennas are structurally simple antennas, but they amount to a relatively large amount of wire. Altogether, the element, radials, support ropes, and especially the guy wire fishing lines made the process quite tedious. Unfortunately, after cutting the fishing line to suitable lengths and rolling out the radials, LB1DJ was struck by sudden illness, and we hastily packed everything down again and went home.

We had initially preferred Saturday as the test day due to the better weather, but now it seemed like we had to make do with Sunday. After waiting until after the worst weather had passed, we returned to the same parking lot from the day before. This time, we remembered everything and were determined to see the antenna in the air.

Laying out all the radials, ropes, and especially the fish line guy wires took a while, but around 20.00 they were ready, and we took a short lunch break before filling the balloon.

It was becoming dark, and we had forgotten our headlamps. Luckily, the illumination lights at the parking lot turned on, and we could continue. After filling the balloon carefully, we opened it more when we got comfortable with the air seal.

When it gradually got the shape of a balloon, it became apparent that our prior calculations about the needed amount of hydrogen were wrong. By the time it was full, we had only spent half of the expected amount.

We attached the antenna to the balloon using cable ties and sealed the balloon using rubber bands. We tied a fish line through the rubber bands such that it would tear them off if it was the last thing connecting the balloon to the ground. The idea was that if we lost the other wires, at least the balloon would not drift infinitely far off. It was raining, but there was no wind. I.e. the weather allowed us to fly without the guy wires to the balloon, which simplified the ascension.

With the balloon at full height and the antenna fully vertical, it was a relief to see that our mechanical concept worked. The balloon did not fly off, and the antenna was soundly arranged in the shape of a classical vertical with elevated radials. Unfortunately, an error that later proved to be a faulty coax adapter prevented us from measuring the SWR of the antenna. This made it impossible for us to tune the antenna, which would have to be deferred to field day.

Despite not tuning the antenna, we were happy with the day. We proved that the mechanical concept worked, which was the most exiting uncertainty. Now we were confident enough with the antenna to try it out on field day. Great thanks to LA2CMA for letting us borrow his regulator, LA2HMA for helping with the gas, LA2T for the wire.

A short note on the choice of lifting gas: There are two common options for choosing lifting gas: Helium and hydrogen. Helium is a noble gas, and therefore considered safer than hydrogen which can be explosive in the presence of oxygen. The benefits of hydrogen is that it is cheaper and that helium is a limited resource on our planet. Every time we use it and release it into the atmosphere it disappears to outer space and we cannot reclaim it. For both of these reasons we opted for hydrogen, and chose to account for the safety with other precautions.

What a fun! I finally know how to build a proper antenna for 630m ️ .

️ .

73 & 55 de Manfred DL4IB in Rostock