In the past we have used Brettingen Fort as our QTH during Field Day, but last year we had to find a substitute QTH as the water supply system had broken down. This year we decided to take a look at the matter and after receiving permission from the landlord, LA2QUA and LB0VG packed the car full of tools and drove up to Brettingen Fort at the end of June.

LA2QUA brought his dog, Alpha

The system

Without any knowledge on how the system was set up, we determined that the system consists of two pressure pumps, one of which is placed right after the main water supply. The other pump is placed inside one of the buildings on top, used to further increase the pressure to an acceptable level.

- The main water line, without the pump, supplies 9 bar

- The primary pump, in conjunction with a pressure tank, has to bring the water up approximately 100 meters. This means that it has to supply over 10 bar to reach the top.

- The secondary pump, also in conjunction with a pressure tank, is connected in the water line up top. This serves the purpose of increasing the overall pressure to 5 bar, compared to the 2-3 bar one would get without the second pump.

The main water line

- The primary pump

- The secondary pump

The primary pump was damaged due to one of the bolts spinning loose inside the chamber locking the motor. Since the motor protection for the pump had been bypassed, this ultimately overheated the motor.

To the left is the assembly from the primary pump that got damaged. To the right is the secondary pump. Notice that they look a little different, as the cover for the first pump had jammed itself stuck to the shaft.

The plan

As the two pumps were identical, we decided to try moving the motor assembly from the working pump down to the faulty one. Before we could do so, we had to shut off the valve separating the main water line from the pump tank.

Transporting the “new” motor

Mounting the “new” motor

LB0VG doing the wiring for the “new” pump

Upon trying to fasten the new motor, we discovered that it didn’t turn at all. To avoid spending a lot of time troubleshooting the pump, we decided to move the remaining pieces down to do it the “right way”.

Motor not spinning – no good

We dismantled the original housing for the primary pump from the original water lines, and replaced it with the housing for the second one. As expected, getting this to fit without removing the pipes was quite a challenge. Not only did we have to force the pipes in place, we also had to make sure the rubber gaskets were correctly put.

One rather sad looking rubber gasket

After a lot of swearing, bending and hard work, we finally got the new housing to sit.

The “new” pump in the original state

We mounted the motor again, and tried turning it on – still no joy. As we found out, the pressure on the mounting bolts is crucial for the pump to spin freely. Loosening the bolts ever so slightly allowed the pump to turn and we were able to continue.

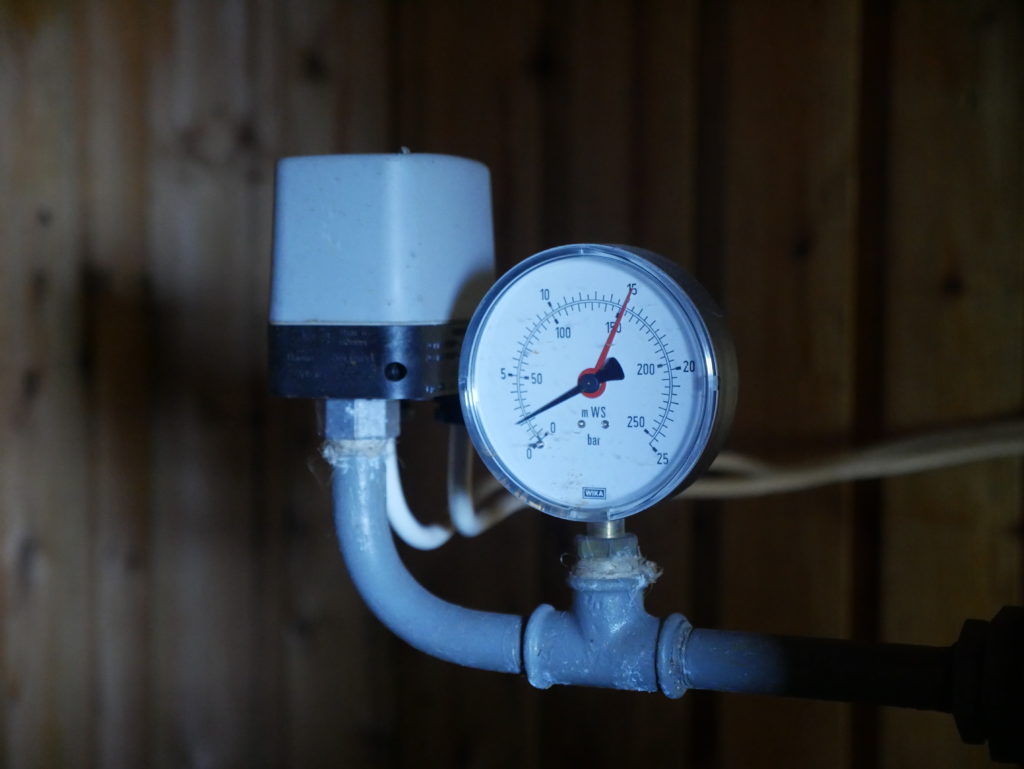

13 bar of pressure is no joke

Another thing we noted was that we had to turn on the water supply carefully to prevent damaging the pump or any of the connections in line. Luckily we found the original manual for the pump and were able to read the instructions for how to bleed and fill up the system correctly.

Pressure slowly increasing

When we were able to confirm that the replaced pump didn’t blow up, we drove to the top and started checking for water inside the buildings. Luckily we had water, however not were we wanted it to be. The previous people on site had removed the blind plugs on several places to avoid freezing and damaging the water lines during winter. We were not informed by this, so we had to trace all the different unplugged lines by opening the main valve and then look for leaky water in the different rooms.

One of the missing plugs behind the toilet – not the easiest to spot

When we had replaced all the covers, we verified that we indeed had water where we wanted it to be. The important question was whether or not we had enough pressure for supplying water to all of the sinks and toilets.

After trying several of the water taps, we were able to confirm that they indeed worked.

The other important thing of note was the toilets, of which we happily could find that worked.

Ultimately this means that we don’t have to bring our own water this weekend, which is good as our equipment is already heavy enough as it is.

Thanks to LA2QUA and Alpha the dog for the help in fixing the water supply!

0 Comments

1 Pingback